Dressing Grinding Wheels: The Key to Optimal Performance in Masonry, Concrete, Contractors, and Roofing

Introduction

In the world of masonry, concrete, contractors, and roofing, achieving high-quality results relies on a combination of craftsmanship, experience, and the right tools. One critical component that often goes unnoticed but plays a significant role in achieving optimal performance is the process of dressing grinding wheels. In this article, we will explore the importance of dressing grinding wheels and how it impacts efficiency, precision, and overall project success.

What is Dressing Grinding Wheels?

Dressing grinding wheels refers to the process of restoring the cutting capability of abrasive tools used in various manufacturing and machining processes. The term "dressing" pertains to the act of sharpening, aligning, and conditioning the abrasive grains on the surface of the grinding wheel, allowing it to efficiently perform its intended task.

The Significance of Dressing Grinding Wheels

Properly dressing grinding wheels is crucial for several reasons:

1. Enhanced Efficiency

A well-dressed grinding wheel ensures maximum cutting efficiency, reducing unnecessary friction and heat generation. This translates into faster material removal rates, minimizing production time and allowing contractors to meet project deadlines more effectively.

2. Improved Precision

Through the process of dressing grinding wheels, the abrasive grains are precisely aligned, resulting in consistent and accurate cuts. This level of precision is especially vital in masonry, concrete, contractors, and roofing where even the slightest deviation can compromise the integrity of the final output.

3. Extended Wheel Lifespan

Regular dressing of grinding wheels helps to maintain their longevity. By removing built-up debris, exposing fresh abrasive grains, and ensuring they are uniformly distributed, the wheel's cutting ability is preserved, reducing the need for frequent replacements and lowering operational costs.

The Techniques of Dressing Grinding Wheels

Masonry, concrete, contractors, and roofing professionals utilize different techniques for dressing grinding wheels based on their specific requirements. These techniques include:

1. Truing

Truing refers to the process of restoring the shape and dimension of a grinding wheel. It involves eliminating any deviation or irregularities caused by wear and tear. The truing process helps in achieving precision and stability, ensuring consistent performance throughout the wheel's lifespan.

2. Balancing

Wheel balancing is a critical step in dressing grinding wheels. Imbalanced wheels can cause excessive vibrations and compromise the accuracy of the cuts. By balancing the wheel, masonry, concrete, contractors, and roofing professionals can maximize both safety and efficiency, while also preserving the lifespan of the grinding wheel itself.

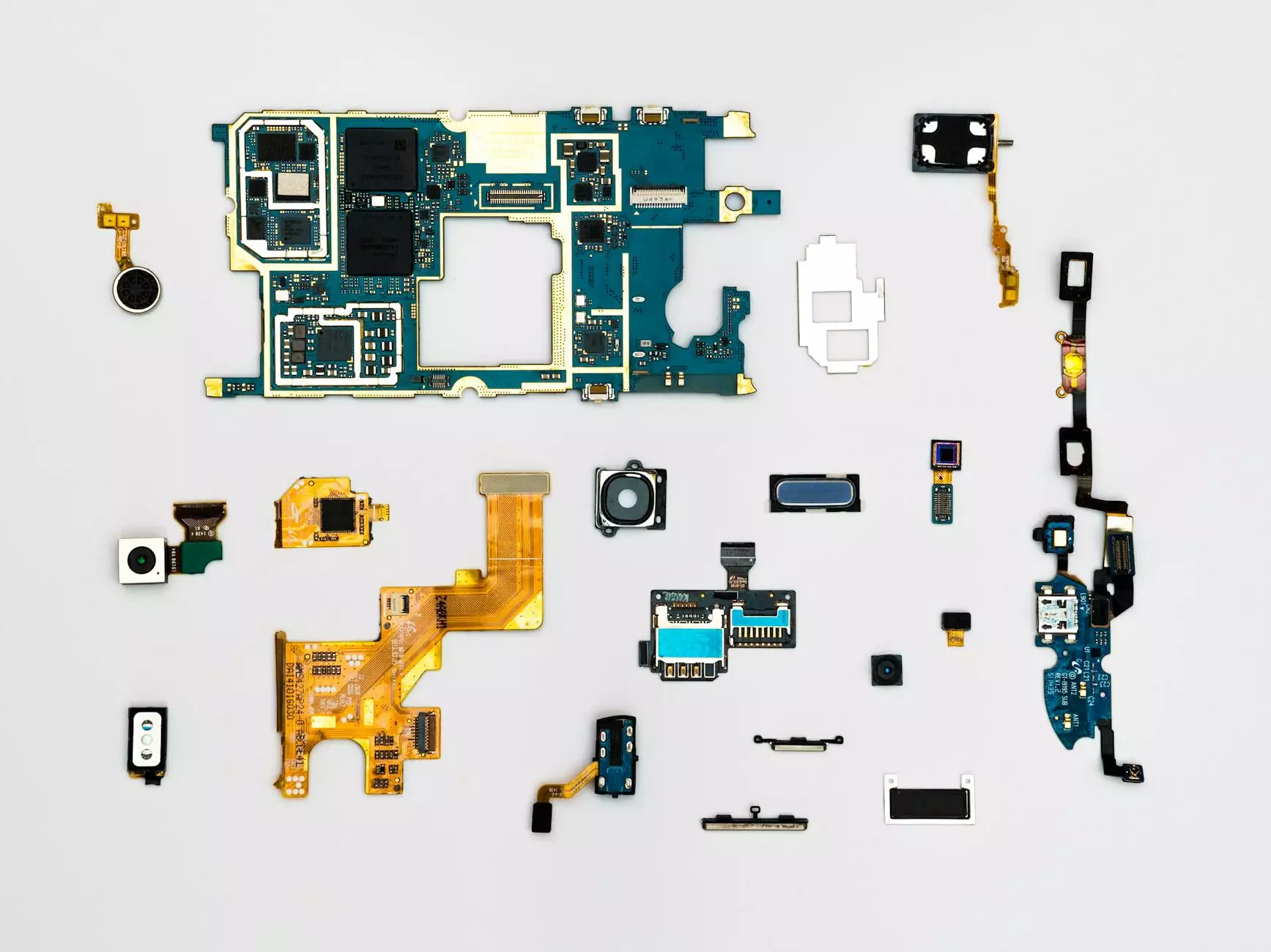

Tools and Materials for Dressing Grinding Wheels

Various tools and materials are utilized in the process of dressing grinding wheels. These include:

1. Diamond Tools

Diamond tools are commonly used for dressing grinding wheels due to their exceptional hardness and durability. Diamond dressers and dressing sticks offer precise control and superior performance, enabling professionals to achieve optimal results consistently.

2. Abrasive Materials

Abrasive materials, such as aluminum oxide and silicon carbide, are used during the dressing process to remove debris and expose fresh abrasive grains. These materials effectively restore the grinding wheel's cutting edge and play a vital role in maintaining its efficiency.

3. Dressing Sticks

Dressing sticks, made from bonded abrasives, come in different shapes and sizes to accommodate various wheel profiles. By holding the dressing stick against the rotating wheel, professionals can restore its true shape and uniformly distribute the abrasive grains.

Conclusion

In the realm of masonry, concrete, contractors, and roofing, the process of dressing grinding wheels is a fundamental aspect of achieving high-quality results. By understanding the significance of dressing, professionals can enhance their efficiency, improve precision, and extend the lifespan of their grinding wheels. With the right techniques, tools, and materials, craftsmen can elevate their craftsmanship and deliver exceptional projects that not only meet but exceed expectations.