Understanding Ultem 1010: A High-Performance Thermoplastic

Ultem 1010 is a crucial material in the fields of engineering and product design. Known for its extraordinary properties, it is a type of thermoplastic polyetherimide (PEI) that offers remarkable strength, heat resistance, and dimensional stability. This article aims to delve deeply into the characteristics, applications, and advantages of Ultem 1010, highlighting its significance in modern manufacturing processes, especially in 3D printing and other engineering applications.

The Chemical Composition and Properties of Ultem 1010

Before exploring the applications of Ultem 1010, it is essential to understand its chemical composition. Ultem 1010 is characterized by its unique molecular structure that provides a balance of rigidity and toughness. Here are some key properties:

- High Heat Resistance: Ultem 1010 has a glass transition temperature of approximately 217°C (423°F). This makes it suitable for applications exposed to elevated temperatures.

- Excellent Dimensional Stability: The material exhibits minimal shrinkage and swelling, ensuring precision in manufacturing.

- Superior Chemical Resistance: Ultem 1010 demonstrates good resistance to a range of solvents and chemicals, making it ideal for various environments.

- High Mechanical Strength: It can endure mechanical stress and strain, making it a go-to for engineering applications.

- Electrical Insulation: As a thermoplastic, Ultem 1010 possesses excellent insulating properties, suitable for electrical and electronic applications.

Applications of Ultem 1010 in Different Industries

Ultem 1010’s properties make it extremely versatile, and it finds applications across various sectors:

1. Aerospace Industry

In the aerospace sector, where performance and safety are critical, Ultem 1010's lightweight and strength-to-weight ratio help manufacturers produce complex parts that can withstand high temperatures and pressures. Components like ducting, brackets, and housings are commonly made from this material.

2. Medical Devices

Ultem 1010 is widely used in medical devices due to its biocompatibility and sterilization capabilities. Items such as surgical instruments, diagnostic devices, and drug delivery systems benefit from the material’s high strength and chemical resistance.

3. Automotive Manufacturing

In the automotive industry, components like connectors, under-the-hood parts, and housings utilize Ultem 1010. It contributes to weight reduction, which enhances fuel efficiency and overall vehicle performance.

4. 3D Printing

One of the most exciting applications of Ultem 1010 is in 3D printing. Its high melting point allows for precision printing of complex geometries, making it a favored material in additive manufacturing. Specialty 3D printers that handle high-performance thermoplastics often use Ultem 1010 for producing prototypes and end-use parts.

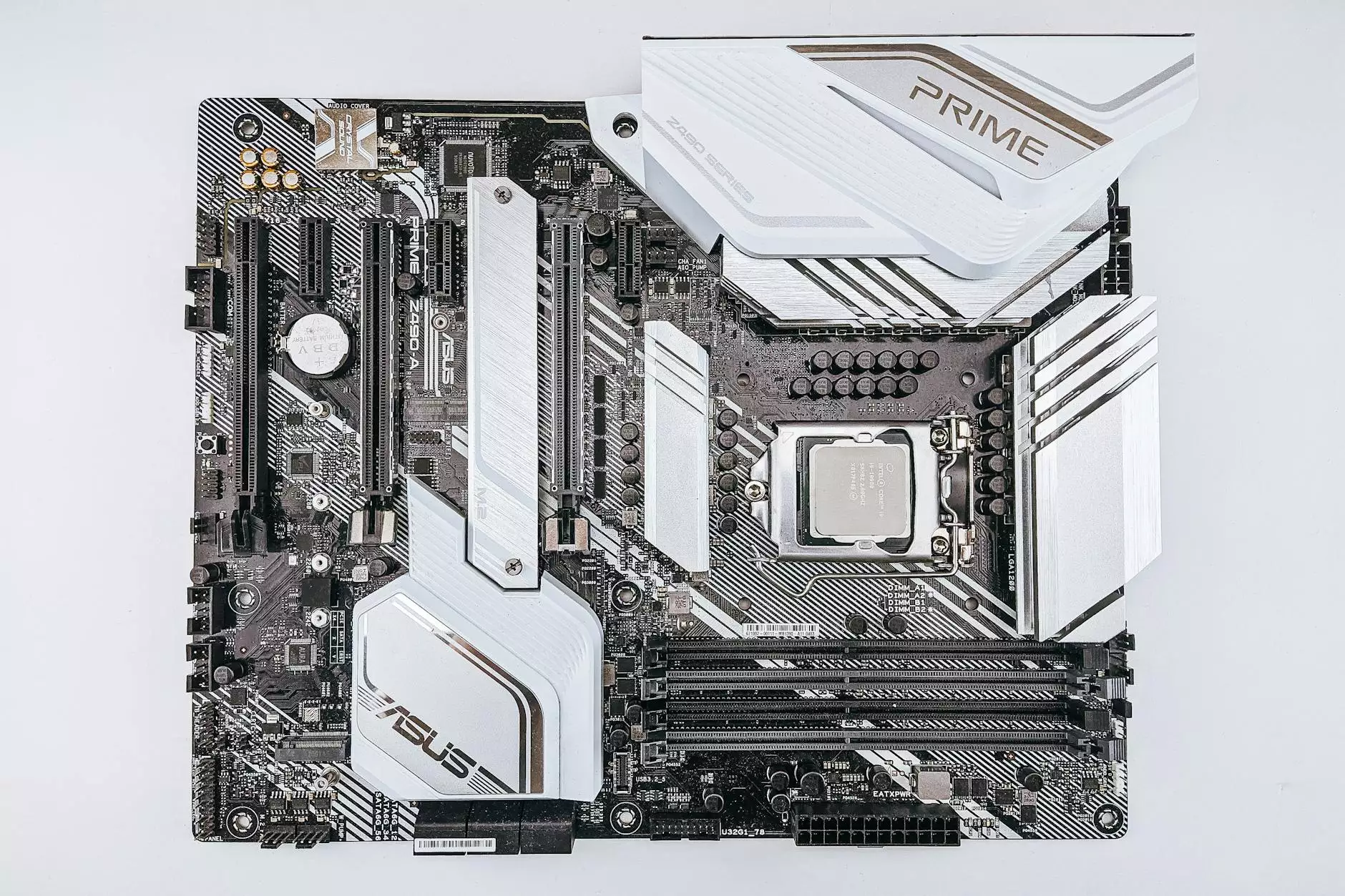

5. Electrical and Electronics

The electrical and electronics sectors leverage Ultem 1010 for components such as insulators, circuit boards, and connectors. Its electrical insulation properties ensure reliability and performance in high-voltage applications.

Advantages of Using Ultem 1010

Choosing Ultem 1010 for engineering applications comes with various benefits:

- Durability: The resilience of Ultem 1010 minimizes the risk of part failure, extending service life.

- Design Flexibility: It supports complicated designs and can be molded into various shapes, fostering innovation in product design.

- Cost-Efficiency: Although it may have a higher upfront cost than other materials, the durability and performance can lead to lower overall lifecycle costs.

- Weight Savings: Its lightweight nature contributes to greater energy savings, especially in industries where weight is critical.

- Compatibility with Production Methods: Ultem 1010 can be used in various manufacturing methods, including injection molding and 3D printing, streamlining production processes.

Comparative Analysis: Ultem 1010 vs. Other Thermoplastics

When considering material options, it is beneficial to compare Ultem 1010 with other thermoplastics, such as POM, ABS, and PLA. Each thermoplastic has its unique characteristics, however, Ultem 1010 stands out for specific applications, especially where heat and chemical resistance are paramount.

- POM (Polyoxymethylene): Known for its excellent mechanical properties, POM is suited for precision parts, yet it lacks the high-temperature capabilities and chemical resistance of Ultem 1010.

- ABS (Acrylonitrile Butadiene Styrene): ABS is widely used in consumer products due to its ease of molding, but its thermal and chemical resilience does not match that of Ultem 1010.

- PLA (Polylactic Acid): A popular choice for 3D printing, PLA is biodegradable and easy to print with. However, its thermal performance is inadequate compared to Ultem 1010.

The Future of Ultem 1010 in Innovative Applications

Looking forward, the potential for Ultem 1010 in innovation and technology advancements is significant. As industries evolve and demand for high-performance materials increases, Ultem 1010 is likely to see further adoption. The continuous improvement in 3D printing technologies, for instance, may lead to new applications that maximize the benefits of this engineering polymer.

Best Practices for Working with Ultem 1010

For businesses looking to utilize Ultem 1010 effectively, here are some best practices to ensure optimal results:

- Understand the Material Properties: Knowledge of Ultem 1010’s thermal and mechanical properties is crucial for successful application.

- Use Proper Equipment: Ensure that your 3D printer or molding equipment is compatible with high-performance thermoplastics like Ultem 1010.

- Conduct Thorough Testing: Prototype and test to validate that Ultem 1010 meets the requirements of your specific application.

- Consult with Suppliers: Engage with material suppliers to gain insights into the best practices for processing Ultem 1010.

Conclusion: The Dedication to Quality with Ultem 1010

In conclusion, Ultem 1010 represents a remarkable achievement in material science, combining strength, durability, and versatility. Whether it’s for challenging aerospace components or innovative medical devices, Ultem 1010 provides solutions that enhance product performance while reducing costs and increasing efficiency. For businesses in the fields of art supplies, product design, and 3D printing, integrating Ultem 1010 into their workflows not only improves product quality but also fosters innovation and growth.

The future is bright for Ultem 1010 as more industries recognize its advantages. By embracing such advanced materials, organizations can ensure they stay competitive in a rapidly evolving market.